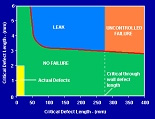

Fracture MechanicsStaff at PP SIMTECH have specialist knowledge and more than 25 years of hands-on experience in the application of fracture mechanics technology to assess defect tolerance of many safety critical and high value pressure vessels and piping. We consider this to be a fundamental strength which supports our risk based integrity assurance technical support services. We also have active representation on the British Standards Institute technical committee for fracture mechanics code BS7910. We have used our expertise in this technology to deliver innovative and highly cost saving solutions to a variety of cracking mechanisms induced problems encountered in service as well as to complement the RBI Assurance process

Types of equipment items where we have carried out these assessments include reactors, distillation columns, pressure swing absorbers, reformer components, steam drum and superheater headers, ammonia storage tanks, other types of pressure vessels and piping, which have been subjected to a variety of cracking damage mechanisms. Capability of PP SIMTECH in reliably matching plant users needs

is demonstrated by illustration of two case study examples. |

|